Non-Standard Customized Automation Equipment Parts

Product Attributes

Brand: RFC

Technics: Cold Pressing

Standard: GB

Usage: Other

Type: Protection Fittings

Supply Ability & Additional Information

Packaging: Carton wooden

Transportation: Ocean,Land,Air

Place of Origin: China

Port: Shenzhen Port

Payment Type: L/C,T/T,D/P

Incoterm: FOB

Delivery Time: 15 Days

Selling Units:Piece/Pieces

Package Type:Carton wooden

For product pricing, customization, or other inquiries:

Share to:

- The name of this product is Non-Standard Customized Automation Equipment Parts. The material is AL6061. The surface treatment is Sandblasting anodized Oxygen. Our company’s medical products are mainly used in ventilators, anesthesia machines, ultrasound and other medical equipment. The materials of product are aluminum alloy AL7075, AL6061, stainless steel SUS316, SUS304, SUS303, insulation materials, PEEK, POM, Polyamide, PEI, Bakelite.

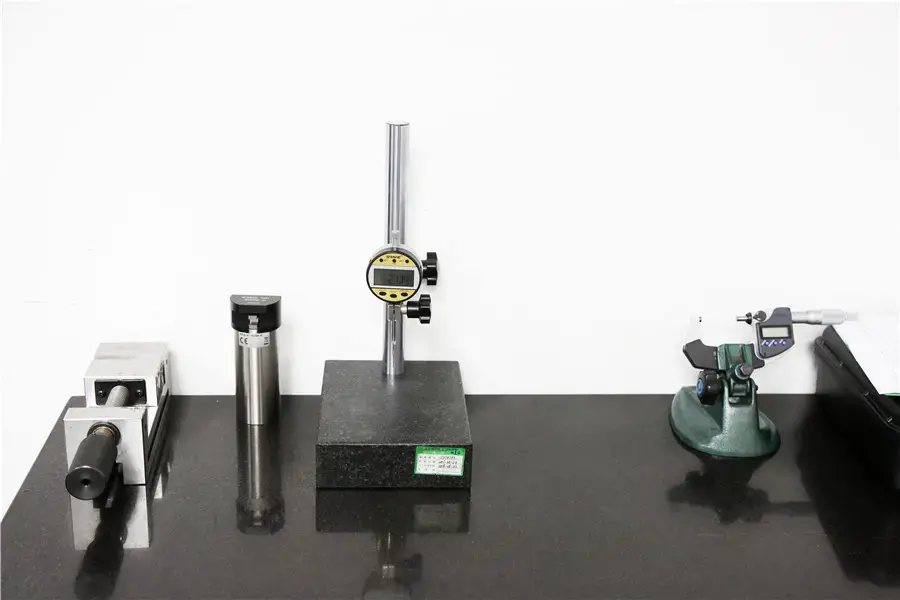

This product is a special-shaped part and cannot be processed by conventional methods. We use a five-axis machining center to process and shape at one time to keep the product’s dimensional tolerance within ±0.01MM and keep position accuracy tolerance within ±0.005MM. The advance equipments of production process mainly are the CNC machining center and Precision Machine Tool Equipment which are mostly turning-milling compound CNC lathe.

Product name: Non-Standard Customized Automation Equipment Parts

Material: AL6061

Surface treatment: Sandblasting anodized Oxygen

Dimensions: 75-51-35mm

Application: Medical equipment

Product Categories : Medical Equipment Precision Parts

Our company adheres to the principle of being friendly to customers, doing our best to help customers solve problems, reduce customer operating costs, thereby improving customer operating efficiency, and undertake mass production of various standard and non-standard precision parts to customers at home and abroad, and can also cooperate with customers flexibly For small batch trial production, our company has large, medium and small high-precision fully automatic production equipment (large gantry CNC machining center, CNC machining center equipment and CNC fully automated turning and milling complex equipment, etc.)

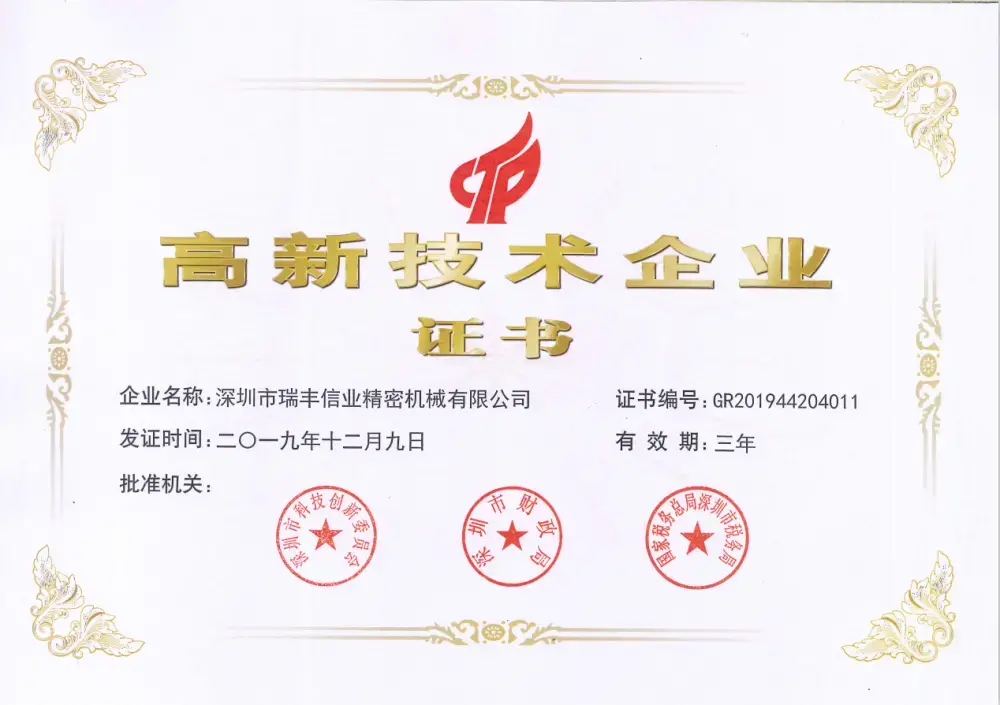

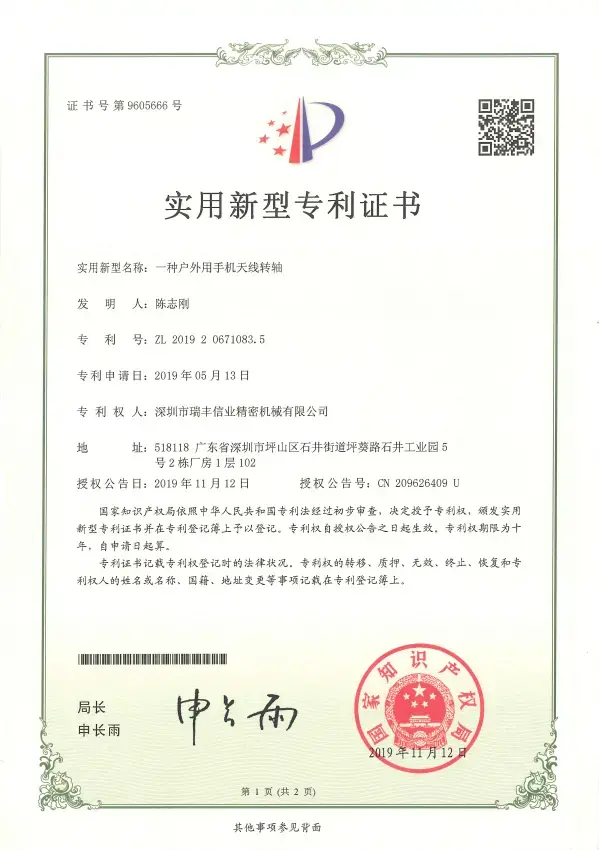

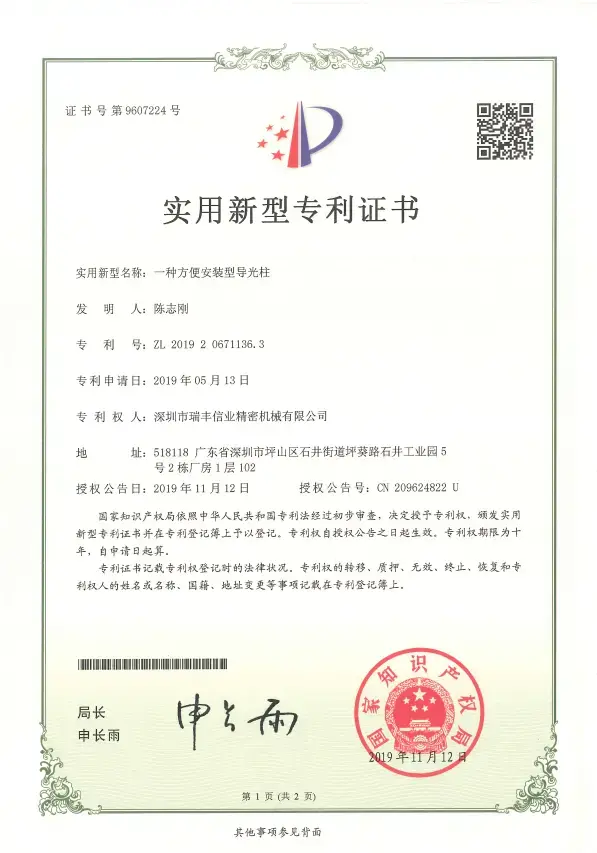

With the expansion of the market and the expansion of production scale, the company has established Hong Kong Ruifeng Precision Machinery Co., Ltd. and Shenzhen Ruifeng Xinye Precision Machinery Co., Ltd. successively. Generations of Ruifeng people are quality-oriented, starting from the little things, and persevering in continuous improvement, making the company’s product quality far ahead in the industry.

We firmly believe that good quality is manufactured, not tested. We integrate the quality awareness of all employees into every step of the manufacturing process, from raw material procurement to processing completion to final packaging and shipment. Every detail in the process has established strict quality inspection standards and implemented them effectively, while using advanced Our quality management methods are strictly controlled at all levels to meet and exceed customer requirements.

In 2006, the company won the ISO9001 quality management system certification and “MOODY” international certification. The company adopted advanced ERP system, TQM management methods and 5S on-site management. The advanced quality control system has effectively improved the quality awareness of all employees. Quality” is the foundation of Ruifeng’s survival. And now the quality of our processed products has also been recognized by many international customers. Through their strict factory audit and professional quality evaluation, they have guided us to become his designated processor in China.