OEM Customized CNC Parts Aluminum product

Oem customized cnc parts aluminum A CNC Computer Numerical Control machine runs on a computer program it can either be for prototyping or in full item production Aluminum is the commonly machined material as it exhibits excellent machinability…

For product pricing, customization, or other inquiries:

Share to:

Productivity: 50000 Pieces/Year

Supply Ability: 50000 Pieces/Year

Payment Type: L/C

A CNC (Computer Numerical Control) machine runs on a computer program; it can either be for prototyping or in full item production. Aluminum is the commonly machined material, as it exhibits excellent machinability, relatively easy to shape, and is thus the preferred material in the most manufacturing sector.

Aluminum is soft, lightweight, tractable, malleable, and durable metal. Its appearance is silver or dull grey and depends on the roughness of the surface. It lacks magnetic properties and its non-flammable. The aluminum metal melts at 640 degrees, and it’s light with a density of 2.68-2.8. It is a good conductor of electricity though not of the same standard as copper on specific cross-section area and is widely used in CNC automotive like ATV, Aerospace and medical industries.

Aluminum alloys have strong corrosion resistance. They are sensitive to high temperatures ranging between 200 and 250 °C (392 and 482°F), and might lose some of their strength. However, the strength of the Aluminum alloys can be increased at subzero temperatures, making them ideal low-temperature alloys.

After-sale Service

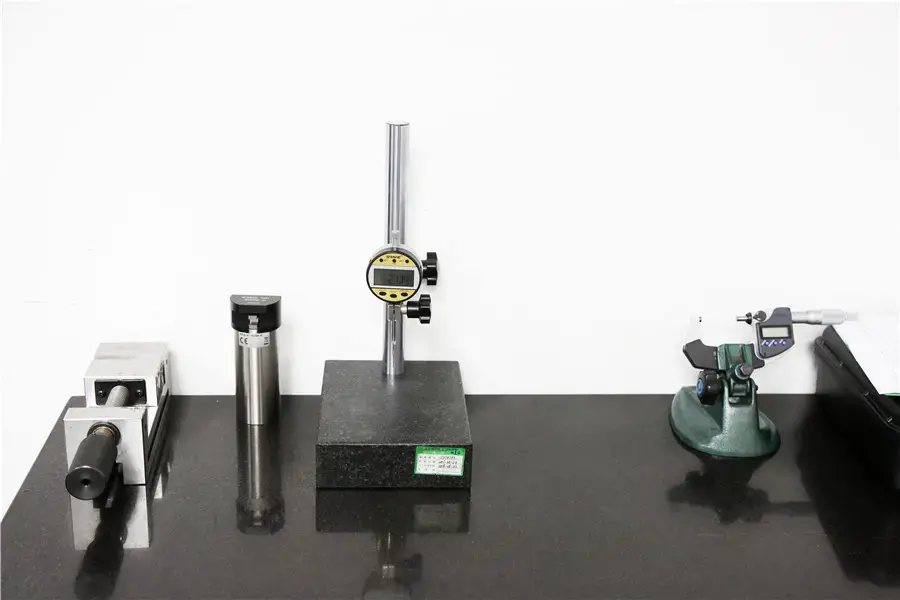

Free quality inspection service

Make the 100% inspection before the shipments

After sending, we will track the products for you once every two days, until you get the products.

When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

Non-Standard Precision Aluminum CNC Machining/Machined/Machinery Parts

Product Categories : Large Gantry CNC Products

Our company adheres to the principle of being friendly to customers, doing our best to help customers solve problems, reduce customer operating costs, thereby improving customer operating efficiency, and undertake mass production of various standard and non-standard precision parts to customers at home and abroad, and can also cooperate with customers flexibly For small batch trial production, our company has large, medium and small high-precision fully automatic production equipment (large gantry CNC machining center, CNC machining center equipment and CNC fully automated turning and milling complex equipment, etc.)

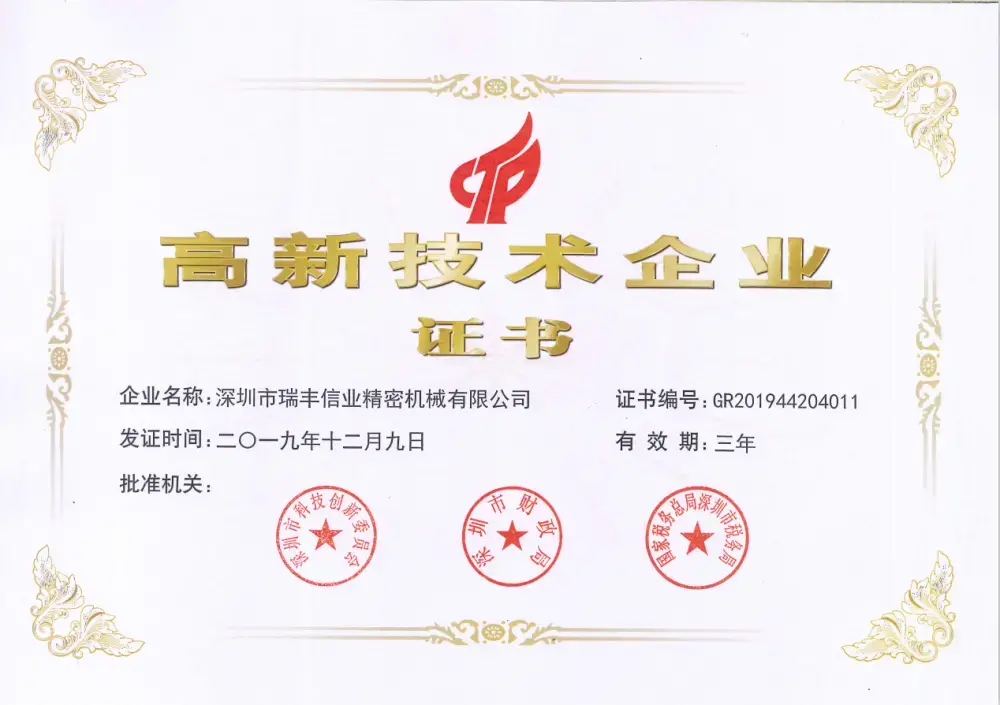

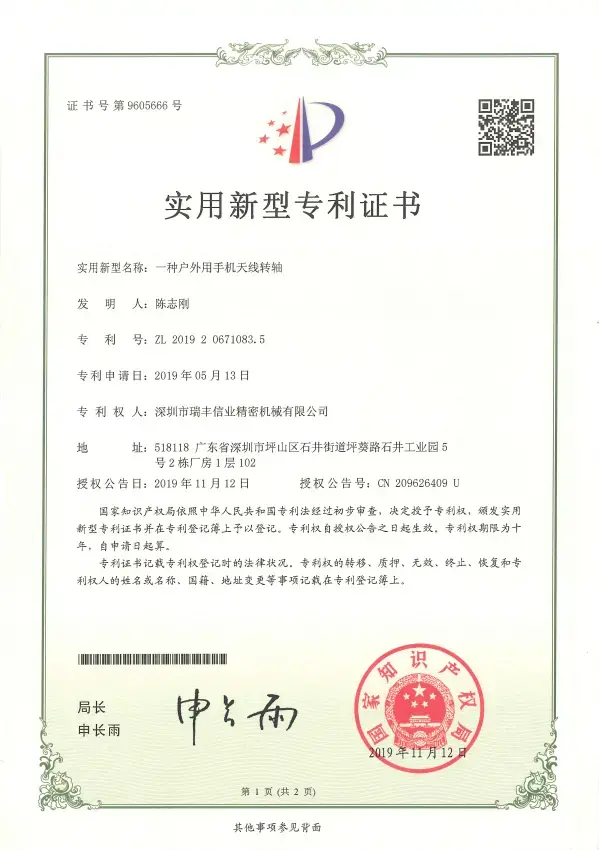

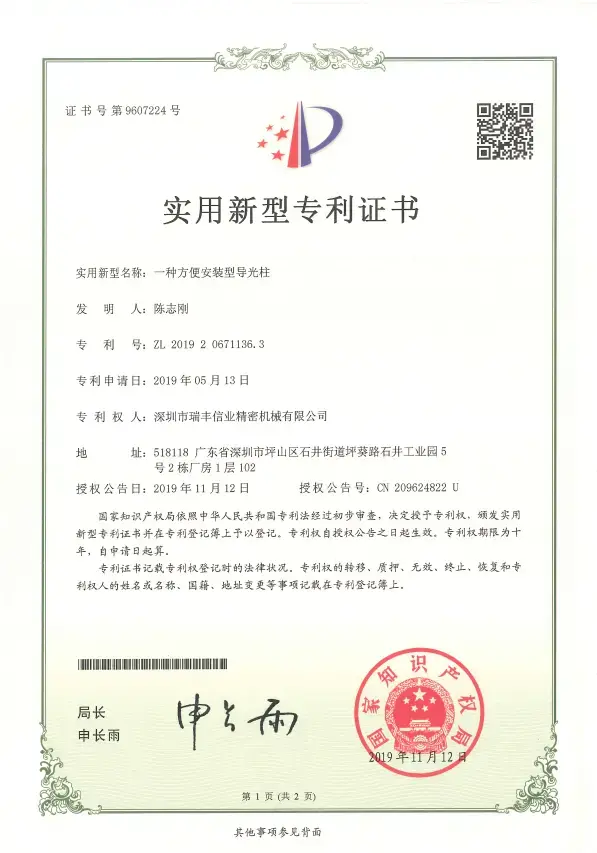

With the expansion of the market and the expansion of production scale, the company has established Hong Kong Ruifeng Precision Machinery Co., Ltd. and Shenzhen Ruifeng Xinye Precision Machinery Co., Ltd. successively. Generations of Ruifeng people are quality-oriented, starting from the little things, and persevering in continuous improvement, making the company’s product quality far ahead in the industry.

We firmly believe that good quality is manufactured, not tested. We integrate the quality awareness of all employees into every step of the manufacturing process, from raw material procurement to processing completion to final packaging and shipment. Every detail in the process has established strict quality inspection standards and implemented them effectively, while using advanced Our quality management methods are strictly controlled at all levels to meet and exceed customer requirements.

In 2006, the company won the ISO9001 quality management system certification and “MOODY” international certification. The company adopted advanced ERP system, TQM management methods and 5S on-site management. The advanced quality control system has effectively improved the quality awareness of all employees. Quality” is the foundation of Ruifeng’s survival. And now the quality of our processed products has also been recognized by many international customers. Through their strict factory audit and professional quality evaluation, they have guided us to become his designated processor in China.