How to improve the finish of CNC machining of auto parts?

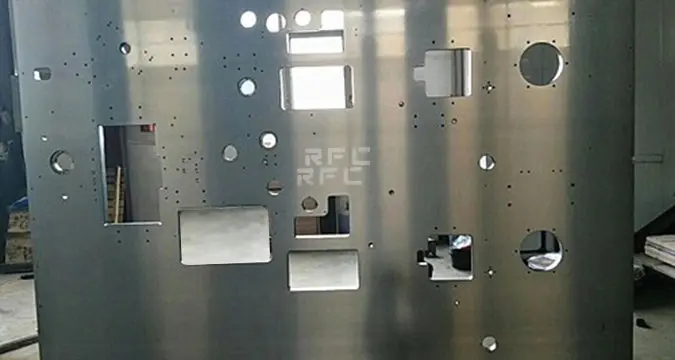

How to improve the finish of CNC machining of auto parts? At present, large-scale CNC machining has become an indispensable and important processing method in the machining of auto parts. When machining large auto parts cnc, you may encounter various problems, such as the pattern and finish of the machined workpiece. So what exactly is the reason behind the low finish off of CNC machining of automobile parts? Today RFC PRECISION MACHINE will introduce in detail how to improve:

The method of cnc machining finish of auto parts:

- In CNC machining projects, try to avoid the high-speed jitter of the spindle, because the jitter during processing will greatly affect the smoothness of the workpiece.

- The chip removal groove of CNC machining should be opened well, and try to avoid the workpiece scratching caused by poor chip removal, which will affect the smoothness of the workpiece.

- If the CNC machining center is not placed uniformly, it will cause vibration and affect the smoothness of the workpiece. Therefore, it is necessary to ensure the stability of the CNC machining center in order to better improve the finish of CNC machining of auto parts.

- Before CNC machining, be sure to match the spindle speed and feed speed of the lathe.

- The CNC machining chip removal groove should be opened well, and try to avoid the workpiece being scratched due to poor chip discharge, which will affect the smoothness of the workpiece.

CNC machining facilities are commonly used in the current machining market, as well as the long term improvement trend is additionally really good. It can be said that most of the parts are related to CNC machining. Especially in the auto parts industry, most of the products are processed by CNC. For example, bumpers, instrument panels, door shafts, transmission shafts, gears, gearboxes, wheel hubs, brake drums, etc., small parts are processed by CNC first, and then glued.