How to judge the rigidity of CNC machining center? The rigidity of large CNC machining directly affects the production efficiency and machining accuracy. The greater the rigidity of the machine tool, the higher the dynamic accuracy, but how to judge the rigidity of the CNC machining center? The following RFC PRECISION MACHINE has compiled some of the contents for reference:

- Selection of section shape and size

For the cross-section of the same shape, in the case of maintaining the same cross-sectional area, it is preferable to adopt a form with a small wall thickness and a large size of the cross-sectional profile. The rigidity of a closed section is greater than that of a non-closed section. Opening a hole in the wall reduces stiffness, but adding a flange around the hole restores the flexural stiffness.

- Selection and configuration of partitions and stiffeners

Reasonable arrangement of support partitions and ribs can improve the rigidity of components. For longitudinal, transverse and diagonal ribs, cross ribs are the best; for some thin-walled components, honeycomb reinforcing ribs are better.

- Improve the local rigidity of components

The connecting parts of the machine tool guide rail and the bracket are mostly parts with weak local rigidity, but the connection method has a great influence on the local rigidity.

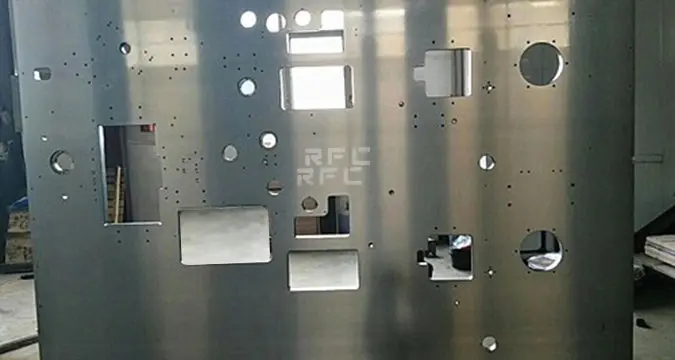

- Select the components of the welded structure

The support parts such as bed and pillar of CNC machining center are welded by steel plate and section steel, which has the significant advantages of reducing weight and improving rigidity. The elastic modulus of steel is about twice that of cast iron. Welding with steel plates can make the components form a fully enclosed box structure, which is beneficial to improve the rigidity of the components.