What are the requirements for materials for precision parts processing? Precision parts processing is not suitable for precision processing of all materials. Some materials are so hard that they exceed the hardness of the part being machined and can cause machine parts to collapse. Therefore, these materials are not suitable for precision machining unless they are machine parts made of special materials, or laser cut.

The requirements are for each job, because it will directly affect the quality of the produced products, so in order to ensure the quality of the products, we must not only have requirements on the equipment, but also on the operators and some processed materials. , These all need to have certain standards, only if these meet the standards, then the products produced can be our ideal appearance, so let us know what are the material requirements for precision parts processing?

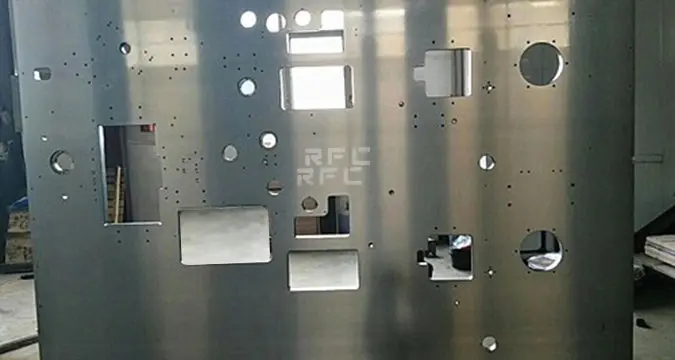

For the materials to be processed, it is divided into two categories, metal materials and non-metal materials; for metal materials, stainless steel has the highest hardness, followed by cast iron, followed by copper, and finally aluminum. The processing of ceramics, plastics, etc. belongs to the processing of non-metallic materials. For material hardness requirements, in some cases, the higher the hardness of the material, the better, but it is limited to the hardness requirements of the machined parts. The processing material should not be too hard; if it is harder than the mechanical part, it cannot be processed; the material must be moderately soft and hard.

It is at least one grade lower than the hardness of the machine parts, and it also depends on the function of the processed equipment and the reasonable choice of the machine. In the process of manufacturing CNC parts, due to the different production requirements and conditions of each part, the manufacturing process plan is also different. When different process schemes are used to produce the same parts, the production efficiency and economic benefits are also different.